Spiral Bevel Gear

What are Spiral Bevel Gears?

Spiral bevel gears are a type of bevel gears, which are used to transmit power between intersecting shafts at an angle of 90 degrees.

Unlike straight bevel gears, which have teeth cut straight across the face of the gear, spiral bevel gears have teeth that are cut at an angle, forming a spiral pattern. This allows the gears to operate more smoothly and quietly than straight bevel gears.

Spiral bevel gears can be designed with various angles and configurations, depending on their specific application. They are commonly used in automotive, aerospace, marine, and industrial equipment, where high precision and reliability are required. They are particularly useful in applications that require high torque transmission, high-speed operation, and low noise and vibration.

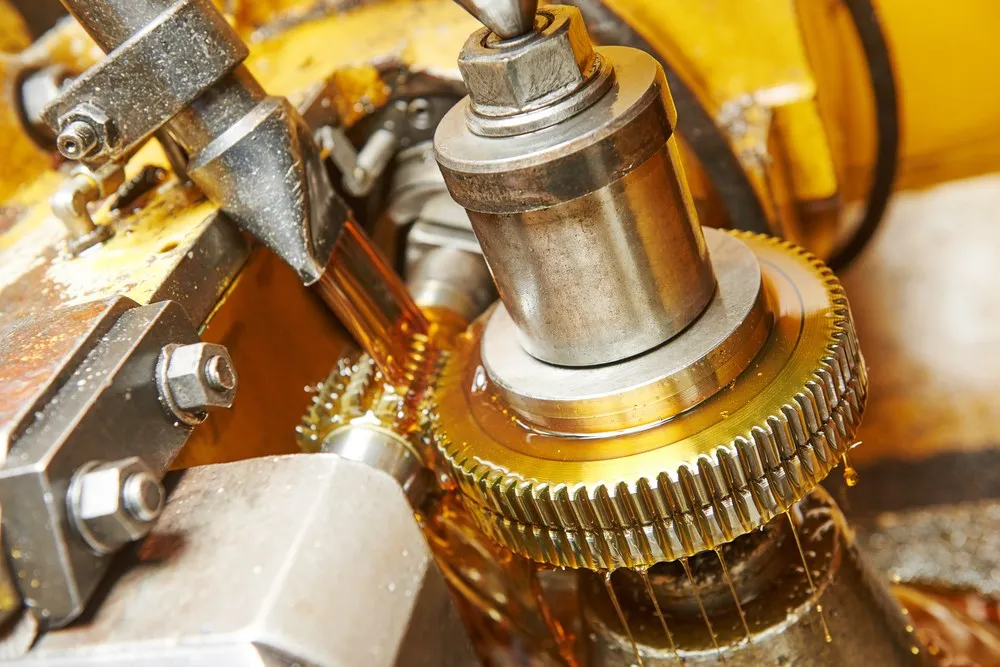

Spiral bevel gears are typically manufactured using advanced CNC machines, which can produce precise and complex gear profiles. The manufacturing process involves cutting teeth into a gear blank using a series of rotating cutters, which progressively shape the gear teeth to the desired profile. After the teeth are cut, the gears are heat-treated and finished to achieve the desired surface finish and dimensional accuracy.

spiral Bevel Gear Applications

Automotive Industry

In the automotive industry, spiral bevel gears are widely used in the differential systems of vehicles to transmit power from the engine to the wheels. The spiral bevel gears used in this application are designed to withstand high loads and torque while providing smooth and efficient power transfer.

Aerospace Industry

Spiral bevel gears are used in the transmission systems of helicopters and aircraft to transmit power from the engine to the rotor or propeller. The spiral bevel gears used in this application are designed to withstand high loads and torque while providing precise and efficient power transfer.

Industrial Machinery

Spiral bevel gears are used in various industrial machinery, such as machine tools, packaging machines, printing presses, and textile machinery. The spiral bevel gears used in these applications are designed to provide smooth, efficient, and accurate power transmission with low noise levels.

Marine Industry

Spiral bevel gears are used in the propulsion systems of boats and ships to transmit power from the engine to the propeller. The spiral bevel gears used in this application are designed to withstand the harsh marine environment and provide reliable and efficient power transmission.

Mining Industry

Spiral bevel gears are used in various mining equipment, such as crushers, mills, and conveyors. The spiral bevel gears used in these applications are designed to withstand the heavy loads and torque of mining operations while providing smooth and efficient power transmission.

Renewable Energy Industry

Spiral bevel gears are used in wind turbines and hydroelectric generators to transmit power from the rotor to the generator. The spiral bevel gears used in this application are designed to withstand the harsh environmental conditions and provide reliable and efficient power transmission.

Advantages of Spiral Bevel Gears

spiral bevel gears offer several advantages over other types of gears, including high load capacity, smooth operation, high efficiency, versatility, alignment flexibility, and long service life. These advantages make them an ideal choice for demanding applications where reliability and durability are critical.

High Load Capacity

Spiral bevel gears have a large contact area between teeth, which allows them to transmit high loads with minimal wear.

Smooth operation

The spiral shape of the teeth allows for gradual contact between teeth, resulting in less noise and vibration during operation.

High efficiency

Spiral bevel gears have high mechanical efficiency due to their large contact area and gradual tooth engagement, resulting in minimal power loss.

Versatility

Spiral bevel gears can be used in a wide range of applications, including automotive differentials, helicopter transmissions, and heavy-duty industrial equipment.

Alignment flexibility

Spiral bevel gears can accommodate misalignment between the input and output shafts, making them more tolerant of installation errors.

Long service life

The high-load capacity and smooth operation of spiral bevel gears result in a longer service life compared to other types of gears.

Design and Manufacturing of Spiral Bevel Gears

The design process for spiral bevel gears involves determining gear specifications, calculating gear geometry, designing the tooth profile, and verifying the design through simulation and testing. The manufacturing process includes material selection, gear cutting, heat treatment, finishing, and quality control. High-strength alloy steel is typically used for spiral bevel gears, and they are cut using specialized gear cutting machines and heat-treated for improved hardness and strength. Gears are finished by grinding, lapping, or honing, and are inspected and tested for quality assurance.

FAQ

Frequently Asked Questions About Spiral Bevel Gear

Can the backlash of bevel gears be measured by examining the pinion?

Although it is possible to measure backlash at the pinion point, be aware that the measurement at the pinion is different from the measurement on the gear.

How do you determine the strength of gears?

Except for HRH gears, the strength of bevel gears is calculated using Gleason's Strength formula. The strength of HRH gears is calculated by using a formula developed by the company which is based upon the results of our in-house tests of strength. The cylindrical strength of gears is determined by using formulas from the JGMA Strength formula.

Do you notice any difference in the efficiency of reverse and forward rotation?

While there may be slight variations depending on the specific product being used generally, pinion efficiency decreases by between 2% and 3% when rotating counterclockwise.

Can I apply a backlash value of zero?

This amount isn't appropriate when metal gears are operating together because of factors like individual gear precision or assembly precision. changes in temperature.

Spiral Bevel Gear for Sale

As a spiral bevel gear manufacturer, we will do our best to serve you. If you need customized products, or the products you need are not found on our website, or need a product catalog, don't worry, more of our products are still being uploaded. You can email us directly, and we will reply to you within 24 hours!

-

Custom 90 Degree Main Drive Differential Spiral Bevel Gear 3 Inches

-

Custom Machining Miter Gear Spur Small Stainless Steel Spiral Bevel Helical Gears

-

Differential Spiral hypoid Screw Spur 90 degree Bevel Helical Worm Gear

-

Spiral Bevel Gear Steering Spline Plastic Nylon Stainless Steel Gear

-

Stainless Steel Metal Straight Sprocket Pinion Spur Helical Spiral Bevel Gear

-

Wheel Hobbing Forged Straight Spiral Bevel Worm Spur Helical Gear

Maintenance and Repair of Spiral Bevel Gears

Maintenance and repair of spiral bevel gears require the following steps:

Maintenance:

- Regular inspection for wear, misalignment, and damage

- Proper lubrication to reduce friction and wear

- Alignment check to prevent excessive wear and noise

Repair:

- Gear replacement or reconditioning in case of severe or less severe damage or wear, respectively

- Shaft replacement in case of damage or wear

- Bearing replacement to restore proper operation

By following these steps, the lifespan and reliability of spiral bevel gears can be increased.

our service:

1. Your inquiry about our products or prices will be replied to within 24 hours.

2. Well-trained and experienced staff answer all your inquiries in fluent English.

3. OEM & ODM, we can help you design and put into products.

Do You Need More Information on These Products?

Fill out the contact form or ask our technical department for a consultation